Sewing using the sewing machine begins with its installation and thorough refilling. In order to get only positive emotions from the sewing process behind a machine, it is important to know exactly how to properly thread a thread, a double needle, a bobbin into a sewing machine.

General procedure

To make the stitch beautiful and durable, it is important to observe one of the basic conditions for effective work: the lower and upper threads must be of the same thickness and quality.

General provisions in which order to thread the sewing machine:

- Starting to sew textile items, from the selected spool you need to wind a little on the bobbin of thread.

- Threading the upper thread. Since each model of the machine has its own characteristics, it is advisable to act on the attached schematic instructional material.

- Threading the lower thread. To perform this stage, the bobbin is placed in a special bobbin case.

- The bobbin case, with the bobbin inside, in the intended part of the mechanism.

Refueling Scheme

- Through the plate along which the fabric advances during sewing, the lower thread is brought to the surface.

- The ends of both threads are under the foot.

Important! The quality of the refueling performed can be checked. To do this, rotate the flywheel so that the needle goes down and rises again. With one revolution of the shaft, a loop should be obtained.

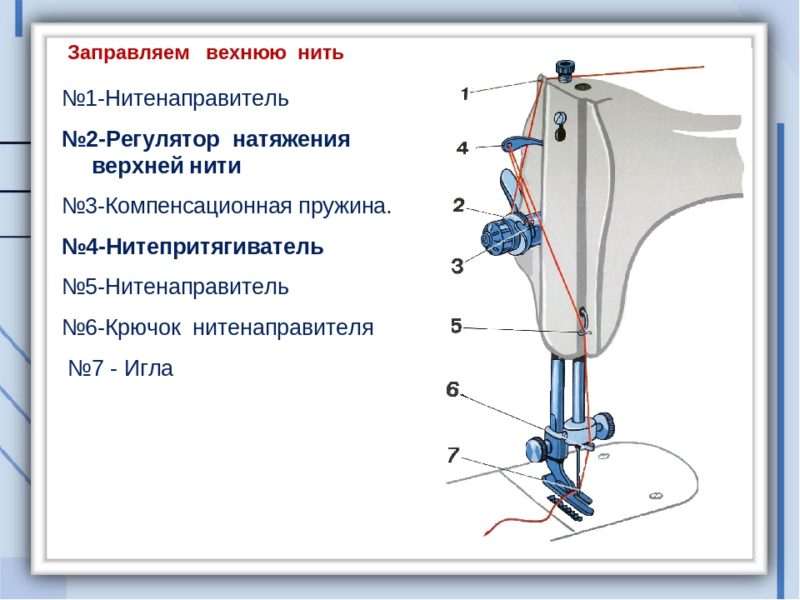

Threading the upper thread

The refueling process has rules, only there are differences in the nuances depending on the make of the machine and the configuration.

Refueling Scheme

Fueling scheme:

- The coil, designed for sewing, is installed on a special pin located on the surface of the device.

- The thread is passed through the mount on the body.

- Then it is carried out between two plates, compressed by a spring.

- Tuck by the hook on the compensation spring.

- Pass through the hole of the thread guide (thread take-up).

- Pass through a rigidly fixed fixture (thread guide and thread guide hook), which is installed near the needle directly on the body.

- The thread is in the needle, then under the foot.

We also recommend reading an article about self-tuning the sewing machine.

Threading the bobbin thread

First you need to bring the bobbin, which is a coil of metal or plastic, into working condition. A thread is wound around it, which when sewing will be from the bottom of the fabric.

For good winding on a typewriter is a special small pin on which a bobbin with several turns of thread made by hand is placed. They fix her there.

Most often, the pin is located near the main shaft. The coil, which is directly wound, is placed on the holder.

The bobbin winder may have an explanation directly on the machine body

The flywheel is switched to the bobbin winding mode and by pressing the pedal or by turning the knob, winding from the reel is performed. After winding is completed, the bobbin reel is taken from the holder and inserted into a cap specially designed for this purpose.

How is winding

Attention! At different trading companies, machines may vary.

Insertion of the lower thread into the sewing machine is carried out in several stages:

- Winding the bobbin to get started.

- After that, it is inserted into the bobbin case. The end of the wound thread is carried out so that it passes through the slot between the two narrow elements. They are attached with a screw to adjust the thread tension.

- Mandatory tension check.

- Next, the bobbin case is installed in the shuttle device.

Perform all actions must be clearly and accurately. If the sequence is disrupted, the machine will not function smoothly.

To answer the question of how to insert a bobbin, you need skill and accuracy in performing the steps:

- The cap is positioned so that the installation finger is facing up.

- They pull the lever of the latching mechanism toward them and insert the cap into the shuttle socket device located below.

Latch lever retraction

- Release the lever, which should give off a distinctive click and lock the bobbin case.

Get an expert opinion on top manufacturers of sewing machines You can in the article on the site.

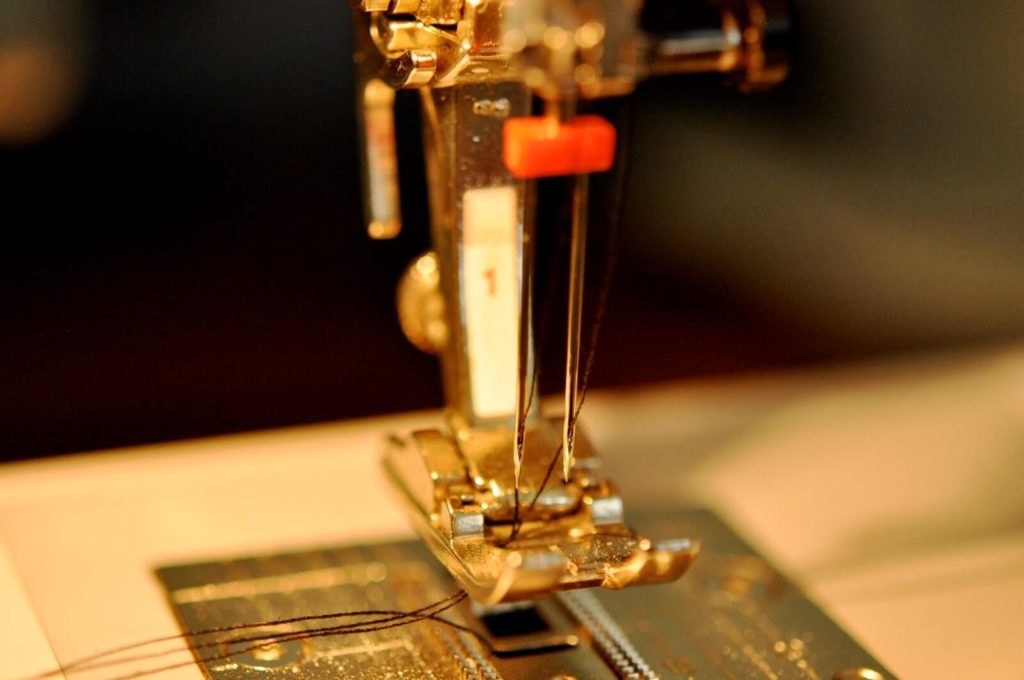

Double needle threading

A double needle in the device can be indispensable in the case when the product must be decorated with a double line (flat or zigzag). For refueling you will need another coil. They should both be the same.

In a manual sewing machine or foot machine, there are two spool holders on the case. Then both ends pass together through the hole in the thread take-up.

Double needles

A double needle is installed based on the same requirements as a regular one. The groove on the needles along which the upper thread should slide must be positioned correctly.

Work order:

- A double needle is installed. It is fixed.

- Both spools are placed on the body of the sewing machine and the threads are passed together as it was supposed to be filled with only one.

- The lower thread guides located directly near the needle should separate them into two.

- Each of them is threaded into the corresponding needle and laid back under the foot.

Important! Make sure that the installed foot is designed for the use of a twin needle.

Correct installation

While sewing things, the double needle is not very different from the usual. The work uses two upper threads and one lower. For the best stitching, its tension must be slightly relaxed.

About the reasons tangles in sewing machines You can read the link.

Sewing Machine Tips

To sewing on a typewriter delivered only positive emotions, you must follow the following recommendations:

- Before starting sewing, lower the foot.

- It is important to choose the correct thickness of the thread and needle relative to the fabric.

- The thread below and on the bobbin should be the same.

- For convenience, it is desirable to have several bobbins with different thread colors.

- Damaged needles should be thrown away without regret.

- The sewing machine must be cleaned and lubricated regularly.

- The handle of the sewing machine should rotate “toward you”. At the same time, it must not be rotated in the opposite direction. To sew backward, it is necessary to move the stitch length adjuster “up” (for a typewriter of the brand “The Seagull”).

- Before work, both the upper and lower threads should be tucked under the foot, with the ends “away from you”.

- After finishing work, put a piece of cloth under the foot. A foot - to lower.

- When working with fleecy materials, periodic cleaning of mechanisms, especially the shuttle device, must be performed more often than when working with non-loose, for example, cotton materials.

- It is necessary to protect the sewing machine from mechanical damage, temperature changes, humidity and dampness.

- When working with a foot sewing machine, it is necessary that the belt from the pulley passes along the starting wheel connected to the pedal. After work, the belt is removed from the starting wheel to prevent it from stretching.

Sewing machine "Seagull"

In order for the sewing machine to serve for a long time, it must be carefully maintained. It must be remembered that being in poor condition, she will not be able to fulfill her main purpose - to sew.

Read also. which threads are best for overlock.

Overlock rating for home by quality 2018-2019

Overlock rating for home by quality 2018-2019  Overview of Janome overlocks: characteristics and features of models

Overview of Janome overlocks: characteristics and features of models  Types of various seams on an overlock (role, flat, rasposhivalny)

Types of various seams on an overlock (role, flat, rasposhivalny)  DIY sewing machine adjustment and adjustment

DIY sewing machine adjustment and adjustment  Rating of the best sewing machines 2018-2019 in quality and price

Rating of the best sewing machines 2018-2019 in quality and price