Water heaters are installed in homes, and in apartments, and in commercial premises. They ensure the constant availability of warm water in the absence of hot water supply and during shutdown of the boiler room. There is no guarantee that the excellent quality of household appliances and installation according to the instructions will help to avoid breakdowns. Often, consumers turn to repair technicians complaining that hot water does not come out of the boiler when it is turned on or its pressure is too weak.

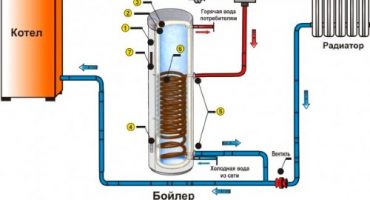

Storage water heater diagram

Hot water does not flow from the boiler: why and how to fix it

The function of the storage water heater is to achieve and maintain the set water temperature. After prolonged use, situations may arise where the pressure of the stream becomes weak or cold water runs from the tap instead of warm water. These problems result from improper maintenance of the equipment, for example:

- scale deposits on the heating element;

- pressure reducer malfunction;

- failure of the thermostat;

- mixer contamination;

- Incorrect heating mode.

Before turning on the equipment, it is necessary to shut off the flow of hot water in the riser and open the tap on the mixer. If this is not done, the air will not exit the tank and the tank will not fill. In addition, the heated water in the riser will go to the neighbors, and the boiler will go cold or stop flowing altogether.

To find out the cause of the breakdown, first turn on the mixer valve, disconnect the device from the mains, empty the tank and proceed with the inspection. You may be able to fix the problem yourself.

Scale

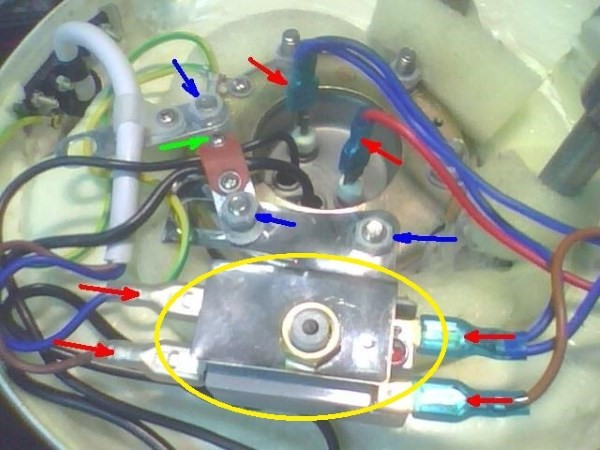

Hard water and high temperature contribute to the rapid deposition of salts on the walls of the boiler and the heating coil. Scale complicates the process of heating water, and violation of heat removal can lead to burnout of the heater. If during the inspection it turned out that the electric heater is covered with a layer of deposits, you must perform the following steps:

- remove the protective cover;

- unscrew the bolts on which the heater is attached;

- remove and clean the part, keeping it in a solution of citric acid;

- put the spiral in place;

- Use the tester to check the contacts.

If after cleaning the heater is operational, then the design is assembled in the reverse order. But what to do when the spiral is out of order? In this case, it is necessary to replace the burnt electric heating element.

Scale on the heater

Pressure reducer

In the water supply system, pressure surges from 2.5 to 7 atmospheres occur. To protect the boiler from deformation due to such differences, a special regulator is mounted on the input to it. After the correct configuration of this unit, water from the drive and the tap flows with the same force. The pressure at the inlet and outlet of the tank should be the same. If the water pressure from the device is too weak, you need to adjust the gearbox or replace it.

Low pressure in cold water pipes can also be the reason for insufficient supply of water from the boiler. To make sure of this, you need to turn the valve in cold water. If it flows in a thin stream or is absent altogether, repair work is probably underway.

Pressure reducer

Thermostat

Water heating does not occur if the thermostat does not include a heater. You can diagnose a part malfunction as follows:

- disconnect the contacts and remove the thermostat from the housing;

- press the fuse button;

- heat the copper tip (the button will turn off if the element is working);

- measure the resistance at the terminals with a multimeter.

Perhaps, the protection against overheating just worked, and the device is restored to working condition. If the tester is silent, the thermostat is out of order, it must be changed.

Thermostat Replacement

Mixer

Water flows out of the boiler in a thin stream - this may indicate a blockage in the mixer. You will need to unscrew the spout from the mixer body, rinse the filter mesh from debris, walk the inner contour with a brush and assemble the structure back. A faulty valve on a hot water tap can also cause low pressure. If the components are very worn out, it would be better to buy a new mixer.

Installing a filter system at the boiler inlet will help to avoid frequent replacement of consumables.

Why does the water heater not fill

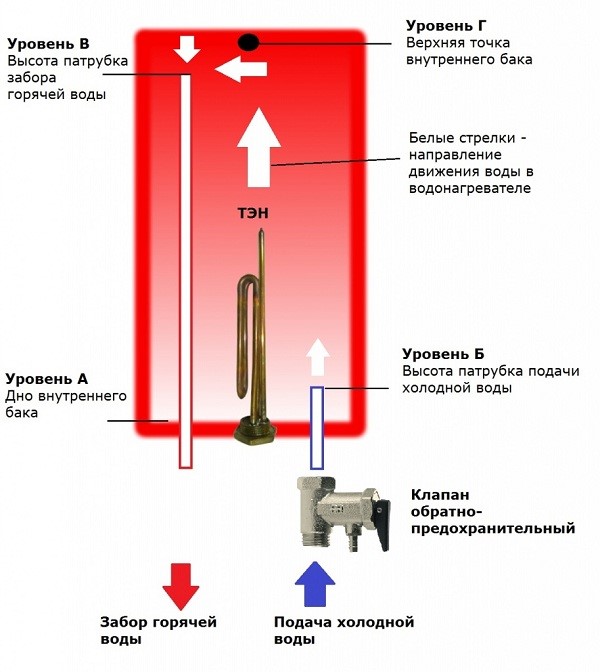

Filling a boiler is simple at first glance. It is important to observe the correct sequence of this procedure:

- the hot water drain tap on the mixer opens, to which the boiler is connected, then the cold tap of the common water supply;

- the liquid gradually fills the tank and displaces the air with a hiss;

- the water level in the tank rises, it begins to overflow into the pipe (level B in the figure);

- when an even stream of water is poured, the mixer can be shut off.

Water flow pattern in a boiler

The water heater is full, only now it should be included in the network. That should be ideal. But it happens that the boiler suddenly does not pick up cold water, although the water supply is working. What can affect this behavior of the heat exchanger?

Filter clogging

At the entrance to the boiler, the water is filtered from impurities. To do this, the design of the device has a strainer that traps litter and rust particles. The gasket from the metal grill becomes dirty, and the garbage stopper prevents the free flow of water. To resume normal filling of the boiler, you need to remove the plug from the bulb and remove the grid. Rinse it in the same way as the mixer filter and put it back.

There are also replaceable filters with gel filling. Poor quality material may leak and clog the tubes through which water moves. If this is your case, then saving the situation will be very simple: you need to buy a normal filter. But you have to try and thoroughly clean the water intake pipes with a brush.

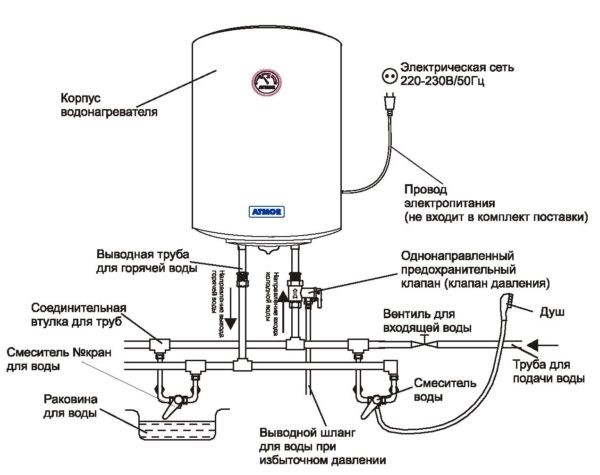

Incorrect assembly

It happens that the cold water intake hose joins the heated drain point, and vice versa. This kind of trouble sometimes happens, especially if the installation was mounted by a beginner. As a result, the functioning of the boiler is disrupted, water does not enter it. The same can be said about the erroneous connection of the safety valve. The problem will be solved by a specialist.

Boiler connection

Check valve defective

In order to keep water in the boiler and prevent its backflow into the general water supply, a safety valve is built into the apparatus structure. It is located after the shut-off valve, at a small distance from the tank, acts in one direction when collecting water. It is also designed to relieve excess pressure: when the water is very hot, the valve's locking device depresses the spring. Excess fluid is vented, pressure stabilizes.

In the worn state or when large particles get into the valve mechanism, it sticks and does not let water into the boiler. It often happens that the chamber behind the Belleville spring clogs with scale. You can restore the functionality of the unit, for this you should unscrew the part, disassemble it into its components and clean it thoroughly. If the attempt to clean up fails, do not leave equipment without a valve.

Check valve

Experts recommend that a check valve with a safety function be installed on the water heater. This will protect the device from the terrible consequences of overheating, such as an explosion.

The water in the boiler runs out quickly

Intensive use of water in the summer and a slight degree of heating will cause the boiler to empty faster. It is also possible that overpressure is created in the tank and a safety valve vents it, releasing part of the hot water. Or, conversely, the low pressure in the main water supply, which does not push cold water into the boiler, is always half empty.

In addition, it is likely that they recently changed the heater to a less powerful one. The position of the temperature controller remains unchanged, and the heater does not cope with heating. There are many reasons why a water heater quickly becomes empty, a few of them are given below.

Leak in the housing

Boilers are made of durable materials that can withstand high pressure and weight. With increased use and poor maintenance, corrosion forms on the inside of the tank — fistulas through which water escapes from the tank. The development of corrosion is affected by:

- salt deposits on the walls;

- scale;

- long downtime in an empty, non-dried state.

If the boiler is rotten, the holes must not be welded. Such a building is not to be used, and there is a place for it in a landfill.

Rusted boiler body

Leakage of compounds

The non-return valve, gearbox and other elements of the sanitary design must be connected firmly, without gaps. The units must be sealed with tow, fum tape or plumbing thread and filled with sealant. If this is not done, poorly secured places will certainly sooner or later let it flow. Unnoticed or obvious, the water will leave the boiler, and this will lead to a breakdown: if the thermal protection does not work, the heater will burn out.

Back pressure relief valve weakness

Water leakage through the drain of the valve can be considered normal if a liter jar is dripped from it per day. These are surpluses that form when the pressure increases from heating. But sometimes the amount of liquid flowing out cannot be determined, since it descends through the discharge hose into the sewer. If at the same time the boiler is unusually quickly emptied, valve weakness can be suspected. In this case, you will have to install a new part, and indeed it is recommended to change this important unit annually.

Water is dripping from the valve - this is normal

It is forbidden to empty the boiler through the opening of the safety valve! Scale and sediment can clog the drainage pores, and the mechanism will stop functioning.

Boiler Maintenance Tips

- No matter how well the water heater is thermally insulated, heat loss can still not be avoided. So do not set the temperature control to the maximum. If the water flow is moderate, it is better to heat it to an average state so that dilution is not required. Strong heating is desirable at a time when you need to take a shower, and you need to draw a lot of water. Lower temperature - less scale.

- If no one is home for several days, the water heater must be turned off, but left full. But nightly shutdowns will not help save energy and even lead to accelerated wear and damage to electronics, often forced to experience overloads.

- After a long period of inactivity, the musty water must be drained, the boiler rinsed and refilled. At maximum mode, warm for two hours, this will help get rid of bad smell and bacteria. When the need to use a boiler, for example, in the winter at the dacha, disappears for a long time, it is emptied, dried well and kept warm.

- A useful element such as a magnesium anode will help reduce scale formation on the walls of the boiler. It dissolves over time, and it is worth replacing it about once a year.But this is a general recommendation, and in each case, you need to think about whether to intervene in the operation of the equipment. The level of hardness and impurities in water is different everywhere, but if the unit began to crackle and heat up more slowly, it would be nice to disassemble the structure and inspect it from the inside.

Anode for water heater

- To soften the water, you can put a filter at the inlet of the boiler, the cartridge of which is filled with a special resin. This substance displaces magnesium and calcium ions, and instead of them sodium ions arise. Another way to reduce water hardness is to mount a hydromagnetic system. A magnet crystallizes salts, turning them into sludge, then they are retained by the filter.

A properly installed and properly operated boiler can last up to 15 years. A variety of factors influence its performance: from water parameters to the quality level of parts and assemblies. In diagnostics and repair, the "random" method should not be used, the main rule is to follow the instructions.

Everything about boilers - from choice to connection

Everything about boilers - from choice to connection  How to disassemble a boiler using the example of Ariston, Gorenje, Termex models

How to disassemble a boiler using the example of Ariston, Gorenje, Termex models  Why the boiler does not turn on on the example of Termex and Ariston

Why the boiler does not turn on on the example of Termex and Ariston  Internet thermostat RODOS-16 - smart warm home in autonomous conditions

Internet thermostat RODOS-16 - smart warm home in autonomous conditions  Faults and repairs of the boiler Termex, Ariston and other brands

Faults and repairs of the boiler Termex, Ariston and other brands