A microwave oven belongs to the category of complex electrical household appliances, so breakdowns of this device happen quite often. In many cases, you can repair the microwave yourself, but in order to do this job flawlessly, you need to know how to properly diagnose the device. This article will talk about how to establish the cause of the inoperability of the microwave oven, as well as how to eliminate the most common breakdowns.

How to repair a do-it-yourself microwave

Microwave repair

Before proceeding with diagnostic actions and self-repair of the microwave, it is necessary to study the principle of operation of the household appliance. In a microwave oven, heating is carried out due to electromagnetic radiation, the frequency of which can reach 2.5 GHz. Under the influence of a high-frequency electromagnetic field, intermolecular friction occurs, as a result of which the material placed in the microwave is heated. Household microwave power usually ranges from 500 to 2,500 watts, but almost all devices allow you to adjust this parameter in a very wide range.

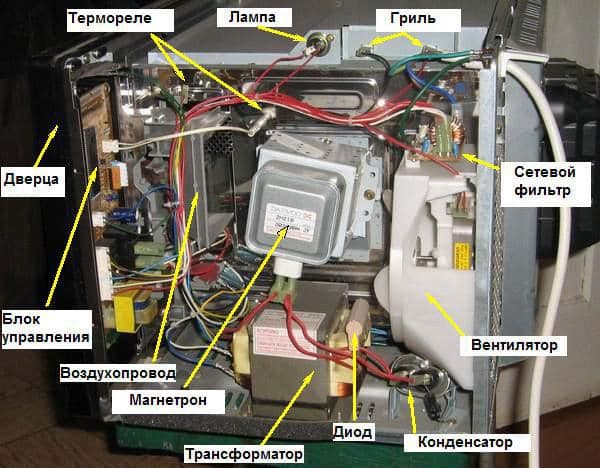

Basic microwave details

Each microwave consists of the following elements:

- Metal chamber with door

- Transformer

- Magnetron

- Control unit

- Waveguide

- Fan

- Rotating table

Before you try to make an independent diagnosis and repair of the device, you should know about the most common breakdowns of the microwave oven.

Types of Microwave Failures

Most often, the following malfunctions can be observed in the microwave:

- Blown high voltage or mains fuse

- Power cord malfunction

- Failure of the magnetron

- Transformer failure

- Failure of the rotary disc motor

- Burning mica pad

Burning mica pad

Not all of the above malfunctions lead to instantaneous inoperability of the device, but the delay in repairing, at first glance, slight deviations in the operation of the device can lead to disastrous results. Untimely repair of such conditions of household appliances can not only lead to the failure of more expensive parts, but also to the spread of electromagnetic radiation beyond the working chamber, which is dangerous to health and electronic devices with microprocessor control.

Next, signs of the most common malfunctions of microwave ovens will be described, as well as options for self-repairing such damage.

Faulty power cord and fuses

If the household appliance does not turn on at all, then the most likely failure, in this case, will be the destruction of the protective fusible conductor or the current-carrying copper core of the power cord. Proceed with direct diagnosis of a household appliance only after the socket to which the household appliance is connected is checked for operability.

It is impossible to diagnose the household appliance itself for a possible wire break or a fuse blowout without first disassembling the device case.

Disassemble the microwave oven only after the device is disconnected from the 220 V.For access to the internal components of the device, for most models of microwave ovens, it is necessary to unscrew several screws holding the back cover, having previously installed the device on its side and closed the door.

After the cover is removed, it is necessary discharge high voltage capacitorbefore proceeding with the repair of electronics. The capacitor is usually located in the immediate vicinity of the transformer. This electronic element can have a rather large charge of electricity, so its conclusions should be closed through a conductor with a resistance of at least 10 megohms.

Diagnostics should be started by checking the electrical cord with the plug. This operation can be performed using a multimeter, having previously activated the resistance measurement mode on the measuring device.

Multimeter

To perform diagnostics, it is enough to measure the conductor from the plug to the terminals on the surge protector board. If the wire turns out to be damaged, it should be replaced either, if the breakage of the copper core is located on the section of the wire located inside the device or in the immediate vicinity of the housing, cut and connect the undamaged length of the electric cable to the filter terminals.

The surge protector is also checked with a multimeter or tester. After transferring the measuring device to the resistance measurement mode, touch the probes on the metal part of this element on both sides. If current conductivity is absent, the part should be replaced. For replacement, it is necessary to choose a fuse that must fully match the voltage and current.

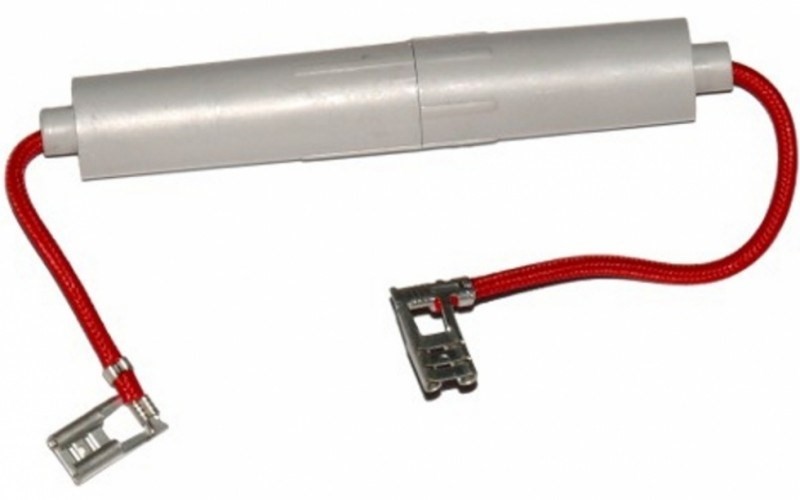

A high-voltage fuse protects the magnetron's electrical circuit.

High voltage fuse

To minimize the probability of breakdown of the conductor to ground, this protection element is usually located in a plastic box. The high voltage fuse is also diagnosed using a multimeter or tester. If the inner conductor turns out to be blown, then the fuse must be replaced with a part that will ideally suit the current-voltage characteristics.

Unfortunately, the malfunctions of modern microwave ovens are not limited to burnout of protective elements and a malfunction of the power cord. Next will be considered no less common breakdowns of microwave ovens, the repair of which will require much more time and money.

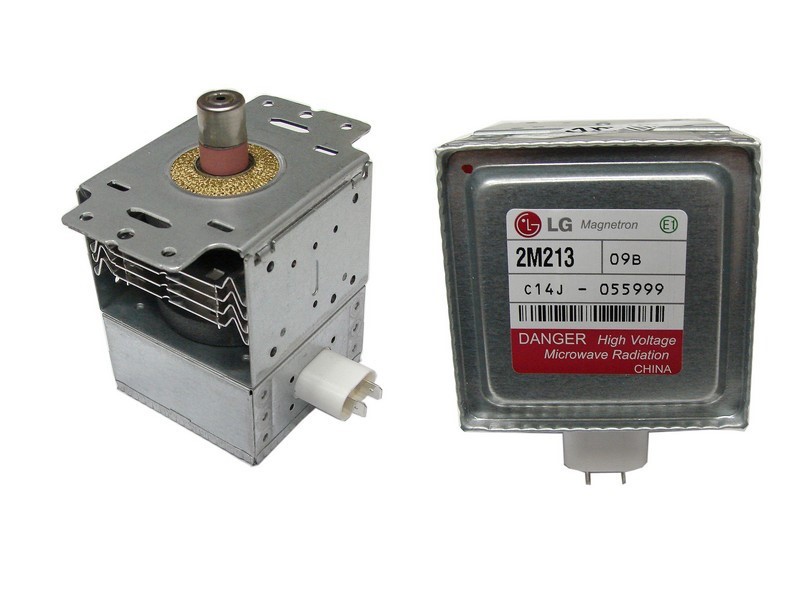

Magnetron malfunction

No less often, microwave failures can be caused by a breakdown of the magnetron.

Magnetron microwave

This electronic component generates electromagnetic radiation, so even a slight deviation in its operation affects the efficiency of heating the products inside the chamber.

The radiation efficiency of the magnetron is always reduced during operation, therefore, if the microwave oven is used for a long time, then to restore the operability of the device, you will need to replace this part with a new one. In a new furnace, the absence of magnetron radiation can be caused by the following breakdowns:

- Reflow cap.

- Breakdown of capacitors on the magnetron mass.

In the first case, the breakdown can be determined visually. There is a melting of the cap as a result of the burning of mica. Repair of such a breakdown can be carried out by replacing the cap of a failed magnet borrowed from a magnetron for another reason. If the magnetron is broken, then its replacement is necessary.

Magnetron cap reflow

If the repair of the microwave oven is done by yourself, then when replacing the magnetron, the following features must be considered:

- The diameter of the antenna and bracket should be ideal for this microwave oven model.

- The magnetron is replaced by a similar device, which should be suitable not only in size, but in power and voltage.

- The magnetron should be fixed with the waveguide as tightly as possible.

- The length of the antenna of the installed magnetron should be the same as that of the failed part.

If the furnace malfunction was caused by the inoperability of the magnetron, then after replacing the part, the microwave can be operated in the usual mode for this device.

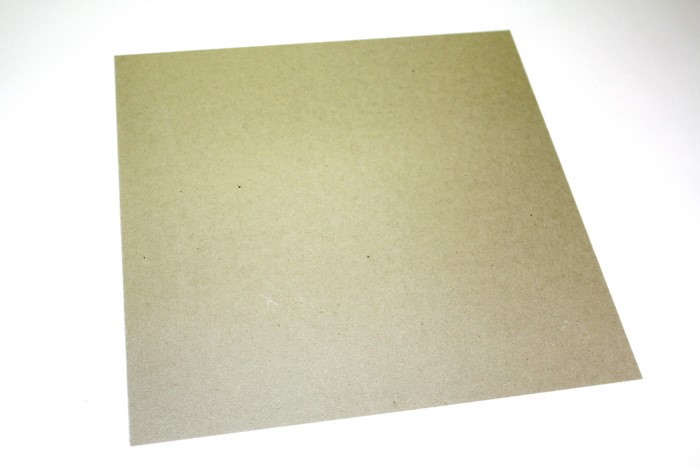

Burning mica pad

This malfunction is most often manifested by sparking inside the camera. Burning out the mica pad practically does not affect the heating efficiency of the furnace, but further operation of the device is fraught with the formation of more serious breakdowns. To repair this malfunction is quite simple.

Mica plate

It is enough to cut out a plate of a suitable size from the new mica material and set it in place of the damaged part.

The plate does not rotate

If the microwave oven starts, but the plate does not rotate, then there may be several reasons for this failure. If there is no rotation of the pan, first check the following details:

- Gear reducer

- Drive motor

- Wire contacts

- The correct installation of the plate

The most common cause of a lack of rotation is a motor failure. The winding of this part may burn out during significant power surges or if it gets wet while washing the inner surface of the metal chamber. Replacing the engine with a known working part will completely restore the rotation of the plate.

A gearbox malfunction can be caused by severe wear of the gears, which can jam during rotation, and in the late stage of wear, the plate may not rotate due to the lack of contact between the teeth. Restore the rotation of the plate in the event of a gearbox malfunction can only be done by replacing the sensor assembly with an electric motor.

Electric motor with gearbox

If the rotation of the plate does not occur due to poor contact of the electric wires with the electric motor, then it is enough to press the contacts with pliers to restore the operability of the electrical unit.

High voltage transformer defective

To convert electric current in a microwave oven, a high voltage transformer is used, a malfunction of which can lead to inoperability of the device. Caution should be exercised during transformer diagnostics because of the potential for hazardous voltage. To exclude the possibility of electric shock, the device must be disconnected from the 220 V network before repair.

You should also discharge the high voltage capacitor through a resistance of at least 10 mOhm. When there is no residual voltage, you can proceed with the diagnosis of the high-voltage transformer.

First, the primary winding should be checked for an open. For this purpose, it is necessary to remove the terminals from the corresponding contacts and use a multimeter, which is included in the resistance measurement mode up to 200 Ohm, to measure the winding. If the primary winding of the transformer does not burn out, the device will show a resistance within 2 - 5 Ohms. Otherwise, the resistance will be completely absent.

Transformer

If the primary winding is intact, then go to the measurement of the resistance of the secondary winding. To ring the secondary winding of the transformer, it is necessary to transfer the multimeter to the resistance measurement mode up to 2 kOhm. To measure the resistance, the probe of the device should be connected to the terminal of the secondary winding, and the other to the transformer housing. Depending on the power of the device, the indication of the secondary winding resistance should be in the range of 140 - 350 Ohms.

With a significant deviation from this indicator, it is possible to diagnose an interturn circuit, the occurrence of which can lead to overheating of the part and excessive noise during operation of the household appliance. With the complete absence of resistance in the secondary winding, it is possible to detect burnout of the transformer winding.

In all cases of inoperability of the high-voltage transformer, it will not be possible to repair this detector on its own, therefore, to repair the microwave, the high-voltage transformer should be replaced with a workable and suitable part in terms of voltage and power.

Conclusion

If the microwave oven stops turning on or does not heat up, then first of all, the cause of the inoperability of the household appliance must be correctly established. Correct diagnostics using digital measuring instruments will make it possible to repair such complex equipment as a microwave oven with minimal costs.

Why the microwave does not work and how to fix it

Why the microwave does not work and how to fix it  Magnetron sparks in the microwave - how to check and replace

Magnetron sparks in the microwave - how to check and replace  Odor from the microwave: how to clean with proven products

Odor from the microwave: how to clean with proven products  All about microwave grilling: what is it and how to use the function

All about microwave grilling: what is it and how to use the function  How many kilowatts a microwave consumes

How many kilowatts a microwave consumes