Choosing an iron for many is considered a difficult task, because this device must meet all the requirements and perform its functions in a high-quality manner. Particular attention should be paid to the appearance of the sole, because it is the basis of the device. It comes in contact with the fabric, smoothes it, eliminates all the defects that appear after washing and drying things.

Manufacturers of these devices use a variety of coatings for the sole, their huge selection can cause difficulties during the choice of buyers. For this reason, it is worth considering their types and features.

How to choose the perfect iron sole?

The soleplate is an important part of the device. It is she who performs the necessary functions, which consist in smoothing the tissue. But when choosing, it is worth considering important requirements that will help to acquire a high-quality device.

Remember the following criteria and requirements for the selection of the soleplate:

- the base should slide smoothly over the surface of the fabric. The device should slide over the material smoothly and easily, while the user should not exert pressure and impact. The highest coefficient can be obtained with a small friction force of the device, which manifests itself during the contact of fabric and the surface of the iron;

- the sole should gently affect the structure of the fabric. It is important that the iron completely smooths the material without obvious damage to its structure. After smoothing, there should be no stretch marks, creases, glossy areas, various damage on its surface. The device should not burn or melt the fabric during ironing;

- uniform heating of the surface. It is important that the sole has the same temperature, this will perfectly iron the fabric without damage;

- high resistance to damage. Preference should be given to models with a sole made of high-strength material. The fact is that it constantly contacts various rigid elements made of plastic and metal, for example, with locks, buttons, and rivets. It is important that there are no scratches, damage, chips on the surface. The base must be resistant to falls, to the effects of various chemicals;

- easy care and easy use. Sole care should not cause any special difficulties. It is recommended to select a device with a base of such a material from which it will be possible to easily remove various impurities that have burnt fibers.

Find out, how to descale the iron at home.

Types of base material

The strength of the sole, its slip, its effect on the fabric depends on the material of the sole. Preference should be given to durable substrates that have a protective coating. That it prevents the formation of dirt, plaque, damage to the sole.

Aluminum

With a sole from aluminum, budget models of irons are usually produced, which is why they are very popular among many consumers. In addition to low prices, aluminum alloy bases have a light weight and high thermal conductivity. But this is where all the positive qualities end.

Aluminum soles have three negative qualities, but they are quite significant:

- low strength. Aluminum is considered a soft metal that must be handled with care. If there is no protective coating on the working surface, then it can be easily damaged, scratched. Damage may occur upon contact with buttons, locks, metal rivets;

- high degree of thermal conductivity.This quality can be attributed to the advantages and disadvantages of the device. Irons with an aluminum surface heat up quickly enough, and if you set the power incorrectly, then with the greatest probability you can leave a burnt spot or hole on the fabric;

- When ironing things from a woolen fabric, shiny spots and stripes remain on the surface of the aluminum sole. For this reason, before ironing, moist gauze should be placed on the fabric.

Many manufacturers of irons with an aluminum sole subject to their anodization, or rather heat treatment. Compared with ordinary ones, the surface that underwent anodizing has improved performance, good strength, and long service life.

Eloxal

Iron manufacturers are constantly trying to improve their products and come up with new technologies by which the surface of the sole becomes stronger and more durable. The well-known company Braun has released a line of devices with the basis of technology made by Eloxal.

Features of the Eloxal sole:

- aluminum alloys are used for production, which are additionally oxidized with an electrolyte solution;

- oxidation makes the metal structure stronger;

- the base is protected against corrosion;

- good glide on the surface of the material;

- does not leave damage on the surface of the fabric.

Stainless steel

Devices that have a stainless steel sole are slightly more expensive than aluminum alloy products. But if we consider the qualities and features, they are much more practical and durable.

The positive qualities of devices with stainless steel soles include the following:

- high degree of strength;

- long service life;

- increased resistance to mechanical stress;

- devices perfectly resist corrosion damage;

- have good glide;

- excellent thermal conductivity;

- the surface warms up quickly and evenly;

- allow to smooth and quality smooth fabrics of any kind;

- stainless steel soles are not expensive.

Only one of the disadvantages can be distinguished - irons with a stainless steel base are quite heavy compared to aluminum. But he is insignificant, all his positive qualities fully justify him.

We recommend that you review the review. the best, according to experts, irons.

Ceramics and cermets

Ceramic and cermet models are very popular among many consumers.

The increased demand for these products is provided due to the presence of a number of positive qualities:

- easy and easy sliding of the device on the surface of the fabric;

- uniform warming;

- threads, rags of fabric do not stick to the surface;

- when ironing on the surface of the material there are no snags, tightenings, various defects;

- easy care. Dirt and deposits can be washed off with a regular sponge.

However, ceramic products have a significant drawback - high fragility. The device can easily be damaged in contact with buttons, locks, metal rivets. And when dropped, the sole may crack or even crack.

Ceramic-metal devices have increased strength. They are able to withstand increased loads, are not damaged by contact with rigid elements made of metal and plastic. But unlike ceramics, they have a high cost.

Steamglide

The well-known household appliance company Phillips not so long ago began to produce devices for ironing with soles using Steamglide technology. The main material used is ceramic or glass ceramics. The coating itself has high strength and easy sliding on the surface of the fabric.

Throughout the sole area there are small holes with different diameters. The main essence of the work is that when ironing, the iron does not touch the surface of the material, but slides on a cushion of steam, which is created using holes.And the influence of steam provides a perfect smoothing of the fabric.

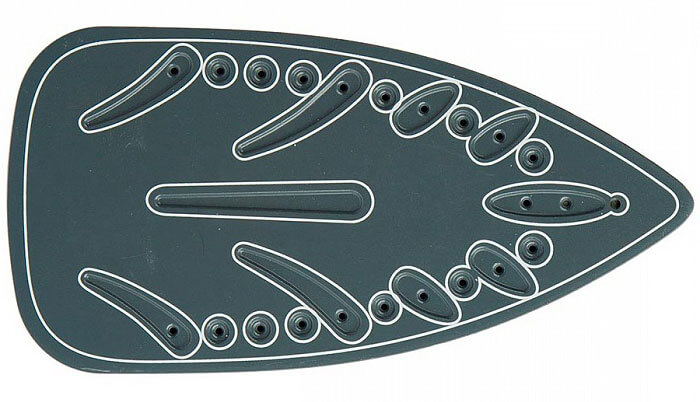

Durilium

Durilium iron sole coatings were developed by Tefal. The base is made of ceramic material. Like Phillips products, there are small holes with different diameters on the entire surface. They are the ones who create the pillow out of steam. In addition, there are additionally longitudinal lines; they, together with the steam holes, create easy glide.

Teflon coating

Teflon-coated iron has many positive qualities, therefore, appliances are very popular. They are ideal for ironing clothes from various types of fabrics.

The advantages of products coated with Teflon material include the following:

- Teflon coatings are quite careful about the fabric. For this reason, devices with a base of this material are often used to smooth things out of delicate material;

- during ironing, threads do not stick to the surface, dirt, no plaque forms;

- easy and simple gliding is provided;

- It does not cause tissue damage, does not cause puffs, clings.

But there are also negative qualities:

- the teflon coating is fragile, it can be damaged and scratched on metal products, plastic;

- due to the fact that the products have low strength, they cannot be placed on metal stands;

- over time, the teflon coating of the iron is completely erased.

Titanium coating

Iron with a titanium sole is one of the most expensive models. This is due to the fact that this metal is the most durable, it is used for the construction of spaceships.

In addition, there are a number of advantages, on which the price of products with a titanium coating depends:

- High reliability;

- Wear resistance;

- It is impossible to scratch a titanium coating, even if it is done on purpose;

- Devices possess simple and easy sliding;

- Easy removal of dirt, soot, but this requires waiting for the complete cooling of the device.

However, there are negative properties:

- appliances have a high price;

- heavy weight;

- prolonged heating.

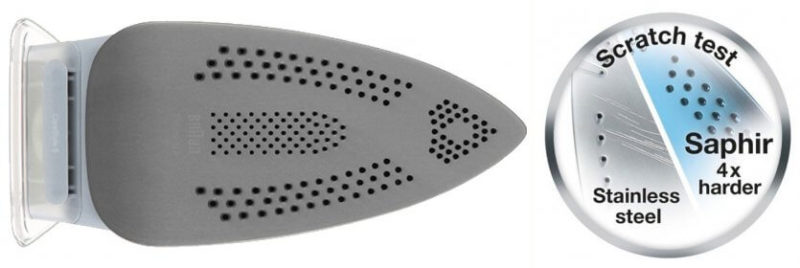

Saphir

The basis of Saphir is an analogue of the titanium coating, in strength it is almost the same. But do not think that it is made of sapphires, the name has nothing to do with the composition of the coating.

The base contains an alloy of the following metals:

- chromium;

- zinc;

- nickel;

- aluminum.

The combination of all these metals has created a high-strength and wear-resistant sole for irons. And according to the properties of strength, it is close to sapphire. Additionally, to improve the quality of the product, the surface is treated with sapphire chips.

As you understand, irons can have a variety of soles, which can vary in strength, wear, and degree of slip. Before purchasing this device, it is worthwhile to first study the properties of the base, the type of material, positive and negative qualities. This will help you choose the most suitable iron for ironing.

See also - which steam iron model choose for home.

When ironing is a pleasure: modern irons and ironing systems

When ironing is a pleasure: modern irons and ironing systems  Ironing Press Overview

Ironing Press Overview  Descale the iron at home

Descale the iron at home  Rating of the best irons of 2019 for quality and reliability

Rating of the best irons of 2019 for quality and reliability  Design and selection of steam irons on the example of popular brands

Design and selection of steam irons on the example of popular brands